Processing technology of plexiglass processing plant

Learn about plexiglass processing plants to understand its processing technology. Plexiglass is a synthetic material. In order to facilitate transportation, it is usually synthesized into a pattern, and then cut according to the desired size and shape to repair the rough edges. , polished and waxed, the finished product has a clear and transparent feeling.

When softening, plexiglass processing plants usually add chloroform, methylene chloride or plexiglass adhesive to bond the plexiglass. These additives can be driven into the next place with a syringe, and after a few minutes of cooling, the plexiglass products are finished. In the thermoforming process, the temperature of the plexiglass is controlled between 80 and 100 degrees during the heat treatment. During the heating process, it is necessary to determine when the bending is most suitable according to the experience of the processing master, and how to ensure a molding.

There is also a bonding process of plexiglass. Some scattered plexiglass are separately processed and integrated. According to the composition, paste with special glue to build a new complete product, plan or grind some scraps, or make some Round the border, then wipe and dust, the joints can not have traces, and according to the customer's custom requirements, through the silk screen, add the business's LOGO, slogan and other content. The bonding process is easy to say, but it is not simple. The degree of splicing is a test of technology and experience. This is also the place to test a plexiglass processing plant.

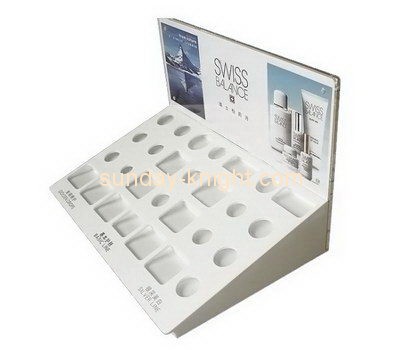

Plexiglass has a strong plasticity, can be made into a variety of jewelry cosmetics display racks, and even a variety of tables and chairs benches, bathtub wine racks, hotel supplies, etc.